ABOUT

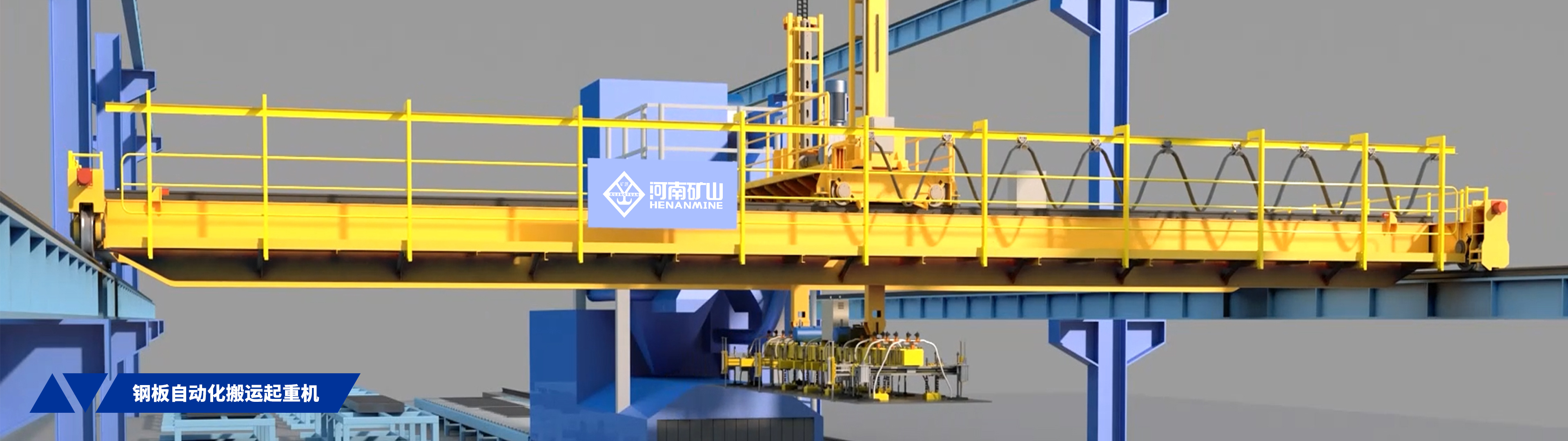

China Donhao Group Co., Ltd. is a professional manufacturer and service provider of cranes and material handling products, integrating research and development, design, manufacturing, sales, and service to provide customers with comprehensive solutions and full lifecycle services.The company has always been committed to the intelligent, green, and high-quality development of the crane industry, leading and participating in the formulation and implementation of industry standards, and providing the most cost-effective products and services to tens of thousands of customers in 122 countries arou...